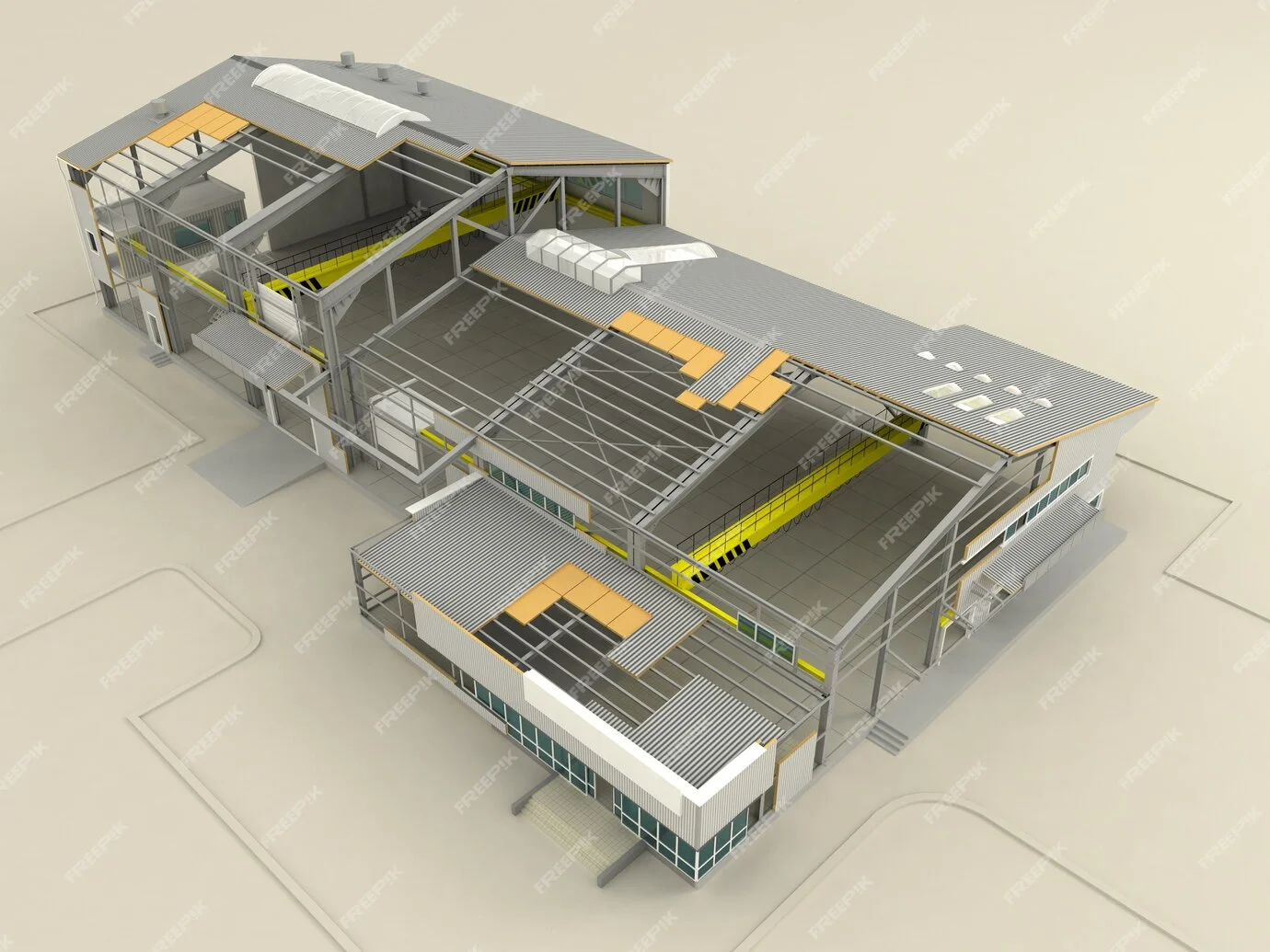

PEB workflow includes design, fabrication, transportation, and on-site assembly, ensuring efficiency, cost-effectiveness, and compliance with building standards.

Custom-built for cost-effective, faster construction.

High-quality, long-lasting steel components.

Streamlined process for rapid

installation.

Choosing the right land is essential for a successful PEB project. The location should be strategically close to raw materials or markets to reduce logistics costs. Proper land leveling is crucial—avoid low-lying areas or valleys to prevent excessive filling expenses. Assess soil quality, as hard rocky strata can increase civil costs. Check groundwater levels, seismic zones, and wind pressure to ensure structural stability. Road connectivity is vital for transporting materials, and local regulations on heavy vehicle movement should be considered. A well-selected site enhances efficiency, minimizes costs, and ensures smooth construction for a durable and stable steel building.

A well-designed land layout is essential for efficient PEB construction and should be planned with expert consultation. Vehicle movement within the premises must be considered from the inception stage to ensure smooth operations. Space allocation for essential utilities like parking, generators, and weighbridges should be included, even if they are to be installed later. Proper drainage planning is crucial, incorporating rainwater harvesting and sewerage drains while considering road levels. An expert-designed layout enhances functionality, prevents future issues, and ensures the long-term sustainability of the site, making operations seamless and efficient for the PEB structure’s success.

Before starting a Pre-Engineered Building (PEB) project, understanding critical milestones is essential to avoid errors and losses.

Land Selection – Choose a strategic location near raw materials or markets. Assess land leveling, soil quality, groundwater levels, seismic zones, wind pressure, and road connectivity.

Layout Planning – Consult experts to factor in vehicle movement, parking, utilities, and a well-designed drainage system, including rainwater harvesting.

Building Design – Optimize foundation, size, machine layout, and load calculations. Plan ventilation, heat insulation, lighting, access pathways, and future expansion. Review the General Assembly (GA) drawing to finalize design details before execution.

A solid foundation is crucial for a stable PEB structure. Ensure PEB design precedes civil foundation work to avoid costly retrofitting. Check the Soil Bearing Capacity (SBC) before civil design. Use a Total Station for precise foundation marking. Align civil structures with the drainage system. Cross-check center lines and anchor bolt positions with the PEB vendor’s GA drawing to prevent disputes and mismatches. Proper land leveling inside the plinth is essential for Hydra movement during erection, reducing costs and delays. Attention to these details ensures a strong, durable, and efficiently constructed PEB structure.

Convert the GA drawing into a GANTT Chart for coordinated reference by the customer, designer, fabricator, and erector. Conduct material inspections before dispatch with a proper checklist. The transporter must carry a Shipper’s list authorized by the PEB manufacturer. The customer must allocate a designated unloading area to stack materials in sequence, preventing haphazard offloading that causes delays and damage. Erection should strictly follow the design without shortcuts to ensure structural integrity. Proper planning, coordination, and adherence to these guidelines enhance efficiency, minimize errors, and ensure a smooth, timely, and high-quality PEB construction process.

A Work Completion Certificate must be issued by the customer to the PEB vendor, ensuring that all minor finishing tasks are completed. Without this certification, small yet essential jobs often remain pending indefinitely.Additionally, the Structural Stability Certificate is crucial for verifying the strength and safety of the PEB structure. The PEB owner should request this certificate from the vendor, confirming that the building complies with design standards and can withstand environmental conditions.For enhanced quality assurance, customers may also request Material Test Certificates, Welding Inspection Reports, and Bolt Tightening Certificates to validate construction integrity.

Innovative, factory-made steel components designed for efficient construction, offering durability, cost savings, and design flexibility.

PEBs offer faster construction, cost efficiency, flexibility, and durability compared to conventional buildings.

Choose Integral Infras for innovative, cost-effective, durable, and timely Pre-Engineered Building solutions tailored to your needs.

Optimized PEB designs to save on your cost of the structure.

Cost savings achieved by increasing production and efficiency.

Total Quality Management Continuous quality improvement process.

Our team of qualified engineers do not learn at customer's cost.

Reach out to us for expert guidance, seamless support, and tailored solutions for your projects.

Find answers to common questions about our services, PEB solutions, and construction processes here.

PEBs are steel buildings designed and fabricated off-site and then assembled on-site for quick construction.

PEBs offer faster construction, cost savings, durability, flexibility in design, and reduced labor requirements.

PEB construction typically takes 30-40% less time than conventional buildings, depending on project size.

Yes, PEBs are used for industrial, commercial, and residential buildings, including warehouses, offices, and factories.

PEBs use high-strength steel, cold-formed purlins, metal sheets, and insulation materials for durability and efficiency.

PEBs are highly durable, weather-resistant, and can withstand harsh environments, making them ideal for long-term use.

Yes, PEBs are highly customizable in terms of design, size, and function to meet specific requirements.

PEBs offer reduced labor costs, lower material wastage, and faster project completion, leading to cost savings.

PEBs require minimal maintenance, with periodic inspections and basic upkeep to ensure long-term performance.

Yes, we offer comprehensive after-sales support, including maintenance, repairs, and technical assistance for PEB projects.

Talk to an expert