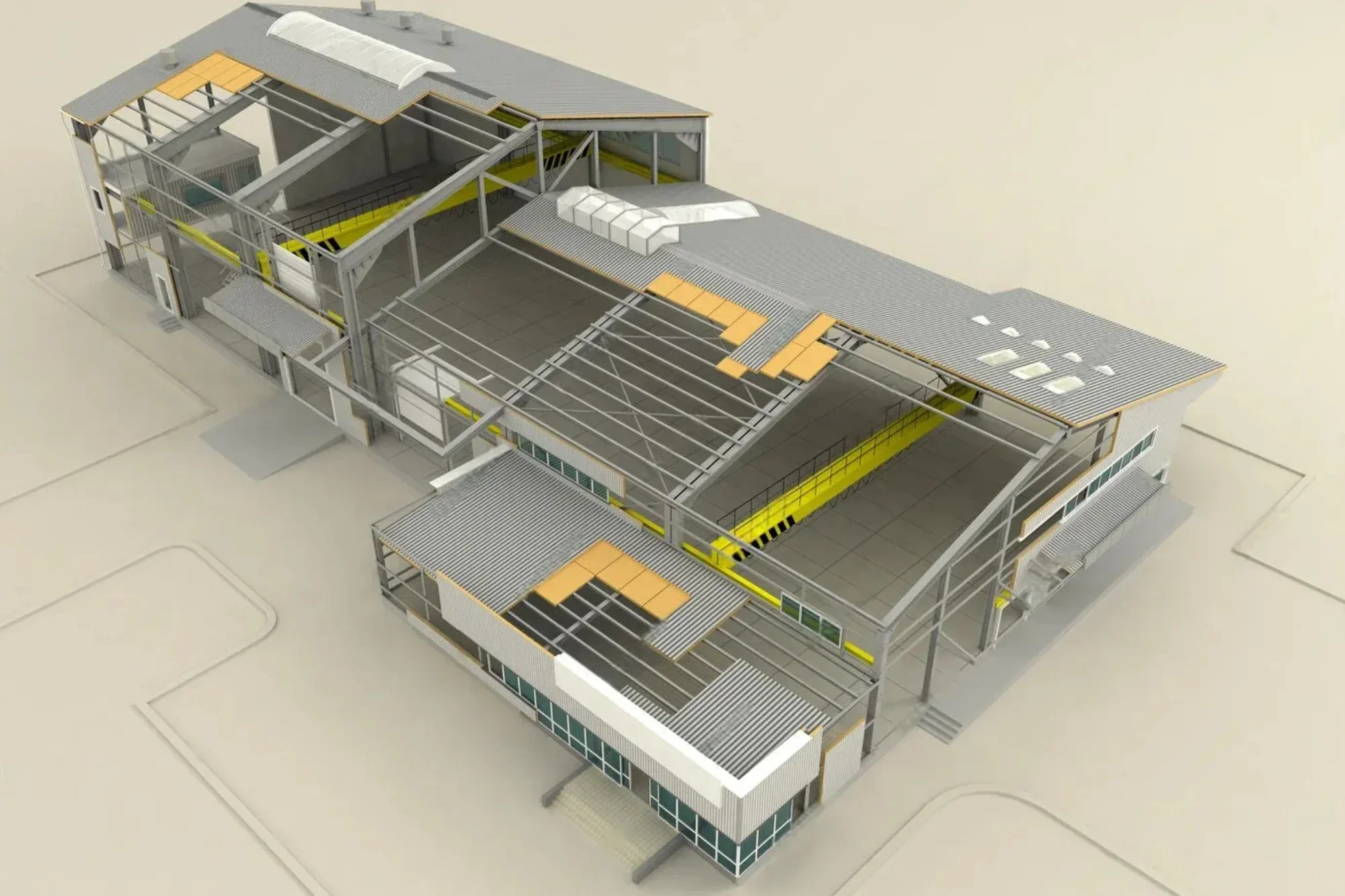

A PEB vendor’s infrastructure ensures quality, precision, and timely delivery, reducing errors and delays for a durable, high-performance steel building.

Custom-built for cost-effective, faster construction.

High-quality, long-lasting steel components.

Streamlined process for rapid

installation.

Production can be backed by 100% stock of raw materials, due to bigger stocking facilities, leading to saving on the batch mode of procurement. For a 100 Tons job, if the batch of procurement is 50 Tons, the second cycle of 7 days of handling the second lot of 50 Tons is saved for the customer in terms of the time of delivery. The customer can decide the value of each day saved!

As a thumb rule, suitable capacity of EOT / Gantry/ Transfer Trolleys / Transfer Conveyors / Cross Transfer mechanism / Flipper Mechanism / Hand pallets / Forklifts / Hydras/ Grabs / Magnetic or Vacuum Lifters

is required in each of the following processes:

Cutting → Splicing → Welding (HBeam) → Fit up → MIG Welding → Grinding → Drilling → Blasting → Painting → Heat Treatment → Stacking → Dispatch

50% of H Beam production time is saved for the customer due to elimination of the time invested in grinding of rough edges. For 10 units of one Ton material each, this saving will amount to one Manday.

Weak welding —> Faults —> Weak PEB Structure —> Non compliance of ASTM / IS standards, normally used for PEB in India. This is because these faults were never considered by the designer.

2 mm steel goes as burning loss if the cutting is done without High Definition Plasma Cutters. You must ask the following questions to yourself.

Evaluate your PEB vendor’s production capability, material handling, and efficiency. Consider daily PEB value, manpower costs, structural durability, and raw material wastage. Who bears the cost of inefficiencies and burning loss? Make informed decisions to optimize resources and minimize unnecessary expenses.

Ensure 100% guaranteed joints with no weak spots. Automated splicers eliminate downtime between splicing and H-Beam feeding, improving production speed. If plates exceed 12 meters, manual splicing negates automation benefits. Verify if your PEB vendor uses automated splicing machines or relies on manual methods, impacting structural integrity and efficiency. Poor splicing can lead to weak connections, compromising the long-term durability of the structure. Advanced automation ensures precise alignment, reducing errors and material wastage.

Automation significantly boosts productivity. Without automation, one H-Beam takes up to 3 hours, while a single automated H-Beam line produces up to 4 beams per hour. A dual H-Beam system with a Flipper and Transfer mechanism delivers up to 10 beams per hour with zero errors.

Normal H-Beam lines handle up to 1500mm web size, 20mm flange thickness, 400mm flange width, and 4 tons per beam. Advanced H-Beam lines manage 1850mm web size, 32mm flange thickness, 680mm flange width, and 9 tons per beam. Primo advanced H-Beam lines are essential for larger PEB structures.

Paint deposition on shot blasted surfaces ensures that Paint (Direct to Metal) has a better life on the metal.

Note: Sand blasting is hazardous from Pollution control point of view. (Not recommended)

Does your PEB vendor have a shot blasting methodology in their infrastructure?

Open-air painting wastes up to 40% of paint, increasing costs. A proper paint booth with a post-painting oven ensures faster curing, improving adhesion and productivity by 300%. A roller conveyor system speeds up processing, reducing manual handling and enhancing finish quality. Without it, paint shops take 50% more time per ton.

Does your PEB vendor offer a paint booth, oven, and roller conveyors to optimize cost, quality, and efficiency?

Innovative, factory-made steel components designed for efficient construction, offering durability, cost savings, and design flexibility.

PEBs offer faster construction, cost efficiency, flexibility, and durability compared to conventional buildings.

Choose Integral Infras for innovative, cost-effective, durable, and timely Pre-Engineered Building solutions tailored to your needs.

Optimized PEB designs to save on your cost of the structure.

Cost savings achieved by increasing production and efficiency.

Total Quality Management Continuous quality improvement process.

Our team of qualified engineers do not learn at customer's cost.

Reach out to us for expert guidance, seamless support, and tailored solutions for your projects.

Find answers to common questions about our services, PEB solutions, and construction processes here.

PEBs are steel buildings designed and fabricated off-site and then assembled on-site for quick construction.

PEBs offer faster construction, cost savings, durability, flexibility in design, and reduced labor requirements.

PEB construction typically takes 30-40% less time than conventional buildings, depending on project size.

Yes, PEBs are used for industrial, commercial, and residential buildings, including warehouses, offices, and factories.

PEBs use high-strength steel, cold-formed purlins, metal sheets, and insulation materials for durability and efficiency.

PEBs are highly durable, weather-resistant, and can withstand harsh environments, making them ideal for long-term use.

Yes, PEBs are highly customizable in terms of design, size, and function to meet specific requirements.

PEBs offer reduced labor costs, lower material wastage, and faster project completion, leading to cost savings.

PEBs require minimal maintenance, with periodic inspections and basic upkeep to ensure long-term performance.

Yes, we offer comprehensive after-sales support, including maintenance, repairs, and technical assistance for PEB projects.

Talk to an expert